Winding & Re-reeling steel wire ropes

DOWNLOAD

How To Winding & Re-reeling steel wire ropes

It is important to attach steel wire ropes at the correct locations on a smooth drum as

improper winding methods will cause the spreading of terns in the first layer of steel wire

ropes on the drum. Then the second layer of wire ropes may be wedged between the open

coils of first layer, crushing and flattening the rope as successive layers are spooled.

Generally, steel wire ropes are wound from the top of the one reel to the top of another or

from the bottom to bottom. But how to start wire ropes on a drum may puzzle lots of our

customers. The following illustration will give you the best solution.

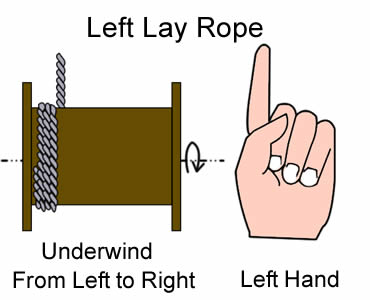

Underwind - left to right

Underwind - right to left

Overwind - left to right

Overwind - right to left

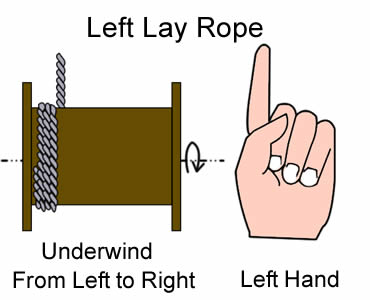

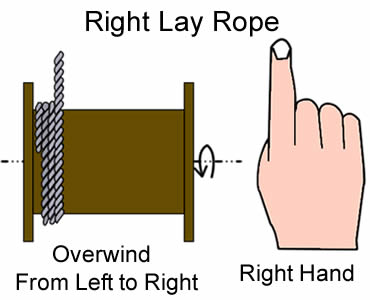

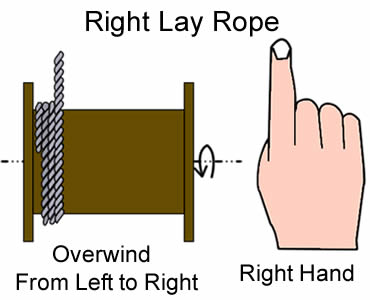

The right hand normally are used to determining right-lay wire ropes and the left hand for

left lay wire ropes when standing toward the drum. The clenched fingers represent the

drum and the extended finger stands for the oncoming rope.

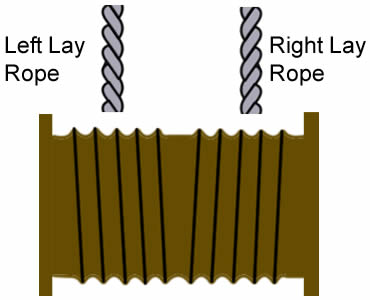

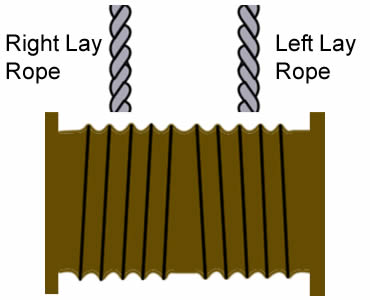

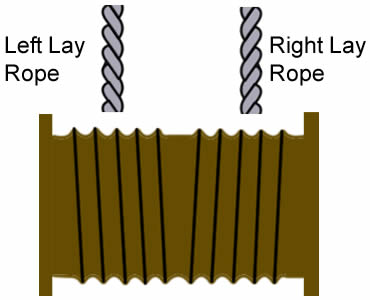

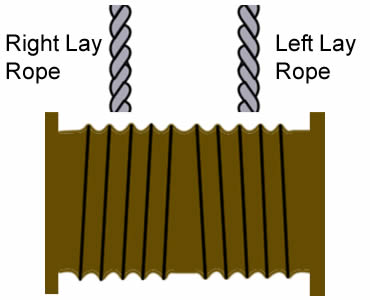

Many crane models also have two sided grooved drums for winding wire ropes as shown in

the picture.

Tow side grooved drums-1

Tow side grooved drums-2

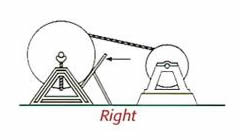

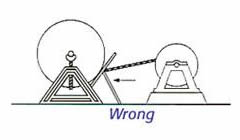

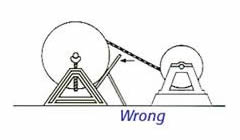

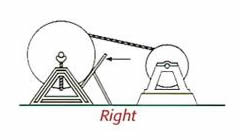

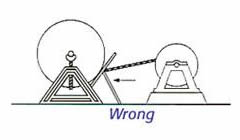

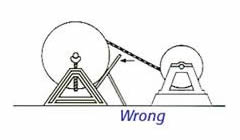

When re-reeling steel wire ropes from horizontally supported reel to another drum, make

sure that the rope is traveling from the top of the reel to the top of the drum or bottom to

bottom to avoid a reverse bend. Look at the following picture about the right and wrong

method of re-reeling:

Right method of re-reeling wire ropes

Wrong method of re-reeling wire ropes

Wrong method of re-reeling wire ropes

Note:

When re-reeling steel wire ropes, make sure the surface of the drum is clean, smooth and

dry to protect wire ropes from damages by foreign particles.

For reels with vertical shafts, re-reeling is also available but you must to ensure the rope is

always taut to avoid accumulation of slack.